Foam Conversion: Enhancing Versatility and Sound Solutions

Foam conversion plays a pivotal role in multiple industries, offering tailored solutions for insulation, soundproofing, packaging, and more. This versatile process transforms foam materials into products designed to meet specific applications. When combined with bespoke acoustics, foam conversion becomes an essential tool for addressing sound and vibration challenges across sectors such as construction, automotive, marine, and manufacturing.

In this article, we explore the concept of foam conversion, its applications, and the innovative bespoke acoustic solutions offered by Acoustafoam. We will delve into the benefits, features, and industrial relevance of these processes, with an emphasis on their adaptability to different needs.

What is Foam Conversion?

Foam conversion refers to the processing of foam materials into specific shapes, sizes, or products tailored to industry demands. This process allows foam to be used in applications such as soundproofing, insulation, packaging, and automotive components. At Acoustafoam, expertise in foam conversion combines precision with cutting-edge techniques to deliver high-quality results.

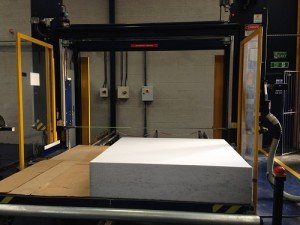

Foam conversion utilizes advanced tools like CNC profiling machines, laminators, water jets, and die-cut presses to transform basic foam materials into technical products. Whether it involves cutting foam to precise dimensions or creating bespoke acoustic solutions, foam conversion ensures adaptability and functionality for diverse applications.

Acoustafoam excels in this area, offering an extensive range of services, including:

- CNC Profiling and Laminating: For creating custom designs and enhancing product performance.

- Water Jet Cutting: For precise shaping of foam materials.

- Spray Booth Coatings: For added durability and functionality.

This flexibility makes foam conversion a cornerstone of bespoke acoustics solutions, particularly for industries requiring sound insulation and vibration dampening.

Applications of Foam Conversion

Foam conversion finds applications in various industries, including:

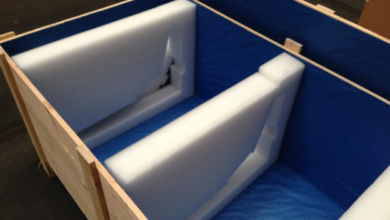

- Packaging Solutions: Foam is cut and shaped to protect delicate items during transportation.

- Insulation: Foam is converted into sheets or profiles for thermal and sound insulation in construction and automotive sectors.

- Automotive Components: Foam is transformed into headrests, armrests, and soundproofing materials for vehicles.

- Medical Products: Foam conversion supports the creation of orthopaedic cushions and medical padding.

- Furniture and Seating: Foam is used to enhance comfort and durability in seating solutions.

The ability to customize foam materials according to size, density, and shape ensures its relevance in meeting specific industrial needs.

Bespoke Acoustic Solutions

Acoustic barriers and soundproofing solutions are integral to many industries, and bespoke acoustics from Acoustafoam address these challenges effectively. These solutions are designed to reduce airborne noise, control vibrations, and improve sound quality in various environments.

Acoustic Barriers

Acoustic barrier products are engineered to minimize transmission loss and dampen vibrations. Key features of these products include:

- Flexibility and Malleability: Allowing barriers to be applied on curved or irregular surfaces.

- Anti-Vibration Properties: Reducing noise caused by impact or movement.

- Thermal Resistance: Reflecting thermal radiation in demanding environments.

Acoustic barriers are used in applications such as:

- Automotive interiors and engine blocks.

- Lift cabins and metal furniture.

- Agricultural and construction vehicles.

- Steel sinks, tubs, and pipe insulation.

The combination of acoustic barriers with foam conversion techniques enables the creation of bespoke laminates for sound absorption and transmission control.

Polymeric Acoustic Barriers

Acoustafoam offers innovative polymeric acoustic barriers such as C03 (1.4mm) and C09 (2.5mm) that enhance the sound insulation of panels made from metal, wood, or plastic. These lightweight barriers are effective across a wide range of frequencies and are particularly suitable for overcoming resonance issues in stiff composite materials.

Specialized Acoustic Products

For environments exposed to heat, such as engine blocks and marine applications, Acoustafoam provides bitumen aluminium acoustic barriers with self-adhesive backings. These products deliver excellent soundproofing performance while withstanding high temperatures.

Benefits of Foam Conversion and Bespoke Acoustics

Foam conversion and bespoke acoustic solutions offer several benefits across industries:

1. Customization

Foam materials can be converted into shapes and sizes tailored to specific applications. This customization ensures that the end product meets exact design and functionality requirements.

2. Versatility

Foam conversion supports a variety of industries, including automotive, construction, marine, and manufacturing. From packaging to insulation, the applications are vast and varied.

3. Enhanced Performance

Combining foam conversion with bespoke acoustics enhances performance by improving sound insulation, reducing vibrations, and offering thermal protection.

4. Durability and Flexibility

Foam materials, particularly polyurethane and polyethylene, are durable, moisture-resistant, and flexible, making them ideal for long-term applications.

5. Eco-Friendly Options

Foam conversion processes often include the use of recycled or sustainable materials, reducing environmental impact.

Innovative Products by Acoustafoam

Acoustafoam is at the forefront of foam conversion and acoustic solutions, offering a range of innovative products:

Polyurethane Foam Mouldings

Polyurethane foam mouldings, also known as integral skin foam mouldings, deliver products that are both durable and aesthetically pleasing. These mouldings are widely used in industries such as automotive, furniture, and gaming. Features of these mouldings include:

- A tough, tear-resistant surface with a micro-cellular foam core.

- Customizable textures, including leather-like finishes.

- UV-stable coatings for protection against sunlight.

Class 0 Foam

Class 0 foam is a high-density, fire-resistant material with exceptional acoustic properties. It is commonly used in engine rooms, generator canopies, and heavy vehicles. Key benefits of Class 0 foam include:

- Non-toxic and CFC-free composition.

- Easy application on curved or complex surfaces.

- Availability in sheet, roll, and self-adhesive forms.

Industries Benefiting from Foam Conversion and Acoustic Solutions

Several industries leverage the advantages of foam conversion and bespoke acoustics, including:

- Automotive: For soundproofing, headrests, and armrests.

- Marine: For thermal insulation and sound absorption in engine rooms.

- Construction: For acoustic and thermal insulation in buildings and vehicles.

- Furniture: For comfortable and durable seating solutions.

- Manufacturing: For custom packaging and insulation.

Read also: Managing Blocked Drains in Baldock

Conclusion

Foam conversion and bespoke acoustic solutions are indispensable for industries seeking versatile, high-performance materials. From soundproofing and insulation to custom mouldings, Acoustafoam provides innovative solutions tailored to meet specific needs.

Foam conversion transforms basic foam materials into advanced products with applications spanning automotive, construction, marine, and furniture industries. Meanwhile, bespoke acoustics, including acoustic barriers and polymeric solutions, address sound and vibration challenges effectively.

As a leader in the industry, Acoustafoam combines expertise, innovation, and customization to deliver exceptional results. Whether you require foam conversion for packaging or bespoke acoustics for soundproofing, their solutions ensure quality, performance, and reliability.

For all your foam conversion and bespoke acoustics needs, don’t hesitate to contact Acoustafoam. They look forward to providing tailored solutions for your unique requirements.