Polyethylene Packaging: Protecting Valuable Goods

Introduction: Understanding Polyethylene Packaging

Polyethylene packaging is a versatile and highly effective solution used in various industries for protecting products during transit, storage, and handling. It is widely known for its robust cushioning properties, moisture resistance, and ability to absorb shock, making it an ideal choice for packaging delicate and valuable items. Polyethylene packaging, including polyethylene foam inserts, offers a reliable and repeatable performance to ensure the safe delivery of goods, minimizing the risks of damage during transportation.

Polyethylene foam is often the material of choice for businesses seeking dependable protection for high-value products. This article explores the numerous benefits and applications of polyethylene packaging, highlighting its critical role in providing a reliable and sustainable solution for companies across industries.

1. The Science Behind Polyethylene Foam Inserts

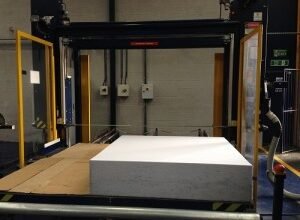

Polyethylene foam is a cross-linked material, which makes it highly resilient and capable of providing long-term protection for various products. Its unique structure consists of multiple cells that act as tiny shock absorbers, absorbing and distributing impact forces effectively. This results in reduced chances of damage, making it especially useful for protecting fragile or delicate products.

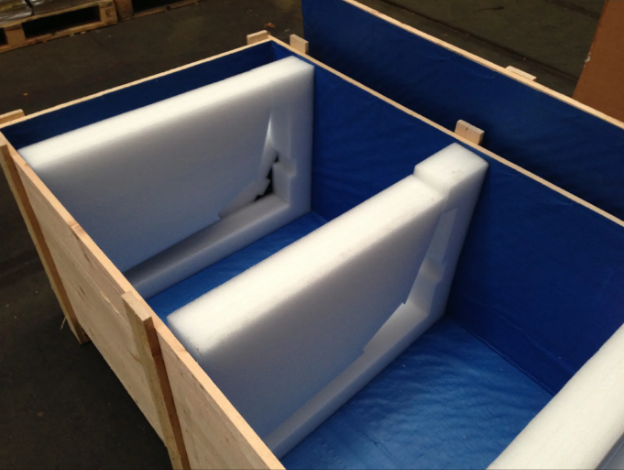

Polyethylene foam inserts are widely used in various packaging designs, where they act as internal cushioning elements, ensuring that products are securely held in place. These inserts can be custom-designed to fit specific product dimensions, further enhancing the level of protection. The foam is available in various densities, allowing companies to tailor the material to meet their specific needs.

2. Why Choose Polyethylene Packaging?

There are several compelling reasons why polyethylene foam packaging is preferred by industries that require high-performance packaging solutions:

2.1 Durability and Resilience

Polyethylene foam is known for its exceptional durability. Unlike other foam materials, such as polystyrene, it can withstand multiple drops and impacts without degrading in quality. This makes it an excellent choice for products that undergo multiple handling processes, such as electronics, automotive parts, and other valuable goods.

2.2 Moisture and Chemical Resistance

Polyethylene foam has a unique advantage over other materials due to its resistance to moisture, chemicals, and temperature fluctuations. This is particularly crucial for industries dealing with sensitive products such as electronics, medical equipment, and pharmaceuticals. Polyethylene packaging provides a protective barrier against moisture and temperature changes, helping to preserve the integrity of the packaged goods.

2.3 Versatility in Design

Polyethylene foam packaging is highly customizable, offering a variety of design possibilities. From tool packs with color combinations to protective inserts for fragile products, polyethylene foam can be molded to meet any requirement. It is available in different colors, including black, white, blue, and anti-static pink, allowing businesses to further customize their packaging to suit their brand image.

2.4 Eco-friendly Options

With growing concerns over environmental sustainability, many businesses are turning to eco-friendly materials for their packaging needs. Polyethylene packaging is available in recyclable forms, making it an environmentally responsible choice for companies committed to reducing their environmental impact. Many companies also offer biodegradable polyethylene options, further enhancing their commitment to eco-conscious practices.

3. Applications of Polyethylene Packaging Across Industries

Polyethylene packaging offers versatile solutions across a variety of industries. Below are some key applications where polyethylene foam inserts and packaging have proven to be invaluable:

3.1 Electronics and Technology

Polyethylene foam is an excellent choice for packaging electronics, as it provides optimal protection against mechanical stress, vibration, and impact during shipping. Smartphones, laptops, televisions, and other fragile electronic components can benefit from the cushioning provided by polyethylene foam inserts, ensuring that they arrive at their destination without any damage.

3.2 Automotive Industry

Automotive parts and components are often subjected to rigorous handling and transportation, which can cause significant damage if not properly packaged. Polyethylene foam packaging provides an ideal solution for protecting automotive parts, such as engines, transmissions, and body panels, during transit. Its resilience ensures that components remain intact, preventing costly damage and reducing the risk of returns.

3.3 Medical and Pharmaceutical Packaging

In the medical and pharmaceutical industries, product integrity is critical, as many items require temperature-sensitive storage and transportation. Polyethylene packaging helps protect these products from moisture, temperature fluctuations, and physical damage. Polyethylene foam inserts can be customized to secure fragile items such as vials, syringes, and medical devices, ensuring they remain safe and secure.

3.4 Art and Antiquities

For museums, galleries, and collectors, preserving the integrity of valuable artworks and artifacts is of paramount importance. Polyethylene foam packaging provides a safe and secure method of transporting and storing delicate items like paintings, sculptures, and antiques. It provides cushioning and impact resistance, ensuring that these valuable items arrive undamaged.

3.5 Consumer Goods and Retail Packaging

Polyethylene packaging is also widely used in the consumer goods and retail sectors. Many businesses rely on polyethylene foam inserts to protect products during shipping and display. From luxury items to everyday consumer goods, polyethylene packaging ensures that products are presented in optimal condition, enhancing the customer experience.

4. Benefits of Polyethylene Packaging

The benefits of using polyethylene packaging solutions are extensive and varied, making it an excellent choice for many businesses looking to improve their packaging processes.

4.1 Cost-Effectiveness

Although polyethylene foam is more expensive than materials like polystyrene, its durability and long-term performance make it a cost-effective option in the long run. Polyethylene foam inserts offer multi-drop protection, meaning that products can be shipped multiple times without requiring new packaging each time. This results in lower overall packaging costs for companies that need to send goods repeatedly.

4.2 Enhanced Brand Image

The packaging you choose for your products says a lot about your brand. Polyethylene packaging not only protects goods but also serves as a powerful marketing tool. Well-packaged products enhance the consumer experience, demonstrating that a business cares about the safety of its products. Additionally, custom designs and the use of branded colors in polyethylene foam inserts can reinforce brand identity.

4.3 Sustainability and Environmental Responsibility

As mentioned, polyethylene foam is available in recyclable and biodegradable options, making it a sustainable choice for businesses looking to reduce their environmental impact. Choosing eco-friendly polyethylene packaging helps companies align with growing consumer demand for sustainable products and packaging solutions.

4.4 Comprehensive Packaging Solutions

Many companies, such as Advanced Protective Packaging, offer complete packaging solutions, from the external carton to the internal polyethylene foam inserts. By sourcing all packaging materials from one supplier, businesses can streamline their packaging processes, reduce stock imbalances, and ensure that all components of their packaging system work together seamlessly.

4.5 Customization for Unique Needs

Polyethylene packaging can be tailored to meet the unique requirements of specific products. Whether you need custom foam inserts for fragile electronics or bespoke packaging for luxury items, polyethylene packaging can be molded and designed to meet your exact specifications. This level of customization enhances product protection and adds value to the packaging.

Conclusion: The Future of Polyethylene Packaging

Polyethylene packaging continues to evolve as businesses seek more efficient, eco-friendly, and cost-effective solutions to protect their products. Whether used in the electronics, automotive, or medical sectors, polyethylene foam inserts offer dependable protection and help ensure that products arrive safely and securely.

As industries demand higher performance and sustainability, polyethylene packaging stands out as an innovative and versatile solution that can be tailored to meet specific needs. With its ability to provide long-term protection, resistance to moisture and temperature changes, and availability in eco-friendly options, polyethylene packaging is poised to remain a crucial component of modern packaging solutions.

Read also: Foam Conversion: Enhancing Versatility and Sound Solutions

Final Thoughts

In conclusion, the importance of reliable and sustainable packaging solutions cannot be overstated. Polyethylene packaging provides businesses with a dependable, cost-effective, and customizable solution to protect their goods during transit, storage, and handling. By choosing polyethylene foam inserts, businesses can ensure that their products arrive safely, reducing the risk of damage and enhancing customer satisfaction. With its many benefits, polyethylene packaging will continue to be a go-to choice for companies looking to protect their valuable products while maintaining their environmental and branding goals.